No products in the cart.

Tornado Fiber Blower w/ Power Pack

Fiber Blower, Tornado Cable Blowing Machine, Includes Power Pack & One Set of Collets & Seals (specify sizes when ordering)

This product is also available through Millennium Rentals and Leasing. For product availability and information, please call 262.581.9099.

Price:RFQ

EA

| Additional Information: |

|

Features & Specifications

-

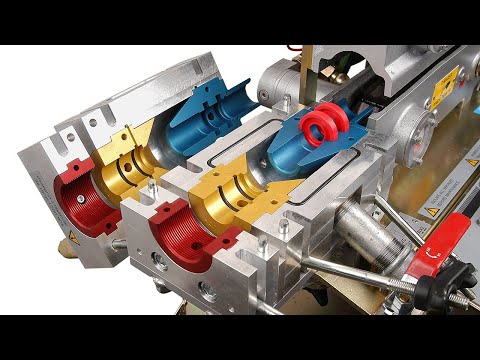

The Tornado Cable Blowing Machine is designed to be safe, fast

and effective, even on tough terrain, the Tornado cable blowing machine will

move fiber optic cable of 0.23 to 1.34 in. (5.84-34mm) diameter

at speeds to 300 ft./min. (90 m/min.) into pre-installed innerduct or

direct-buried duct.

It can accommodate innerduct from .47 to 2.48 in.

(12-63mm). A conversion kit allows the Tornado to place 12.7/10mm, 12/10mm

or 10/8mm micro duct into the inner duct. (sold separately)

·

Comprised of an

aluminum air box and cable pusher, the Tornado uses compressed air to install

the cable with or without a missile. In operation, the hydraulically powered,

caterpillar belt drive system controls the fiber optic cable as it is propelled

by compressed air into the duct. An electronic monitoring system provides

read-outs of speed and distance, protects cable against duct obstructions, and

includes an emergency stop facility.

·

The air box and cable

pusher are mounted on a lightweight, tubular-steel frame that can be tilted at

a 30-degree angle to the manhole, which minimizes significantly any bending of

the innerduct and cable. The frame has height adjustment to permit ease of

maneuverability, and adjustable rear legs that provide added stability on

uneven terrain.

·

Can also be used

without the frame, directly from its skid

·

The Junction Box

Adapter is a necessary accessory for overriding existing cable in an occupied

duct (space permitting). One branch attaches to the Tornado for placing the new

cable or micro ducts, while the other branch seals off and holds the existing

cable in the duct (sold separately)

·

Included with the

Tornado is a convenient toolbox with all the tools needed for use and

maintenance of your blower

·

All relevant parts and

components of the cable blowing machine and the hydraulic power pack are

specially treated to resist corrosion

Operating Capacities

Pushing Force: 0-220 lbs.

(0-100kg)

Pushing Speed: 0-300 ft/min (0-90m/min)

Cable Size: .24-1.34″ (6-34mm) O.D.

Sub – Duct Size: 1/2-2 1/2″ SDR (12-63mm) O.D.

Pneumatic System

Air Hose Bore (min): 1 1/4″

(32mm)

Operating Pressure: 175 psi (12 bar)

Flow: The air

supply should be filtered, cooled and dry

For Ducts with an Inner

Diameter of: Minimum Flow

Acceptable @175 psi (12 bar)

0 up to 1″ (0 up to 25mm) : 150 CFM (4m³/min)

1 up to 1 1/8″ (26 up to 30mm) : 185 CFM (5m³/min)

1 1/8 up to 1 3/8″ (31 up to 35mm) : 250 CFM (7m³/min)

1 3/8 up to 1 5/8″ (36 up to 40mm) : 375 CFM (10m³/min)

1 5/8 up to 1 3/4″ (41 up to 44mm) : 450 CFM (12m³/min)

1 3/4 up to 2″ (44 up to 51mm): 700 CFM 19m³/min

The Tornado Cable Blowing Machine is designed to be safe, fast

and effective, even on tough terrain, the Tornado cable blowing machine will

move fiber optic cable of 0.23 to 1.34 in. (5.84-34mm) diameter

at speeds to 300 ft./min. (90 m/min.) into pre-installed innerduct or

direct-buried duct.

It can accommodate innerduct from .47 to 2.48 in.

(12-63mm). A conversion kit allows the Tornado to place 12.7/10mm, 12/10mm

or 10/8mm micro duct into the inner duct. (sold separately)

·

Comprised of an

aluminum air box and cable pusher, the Tornado uses compressed air to install

the cable with or without a missile. In operation, the hydraulically powered,

caterpillar belt drive system controls the fiber optic cable as it is propelled

by compressed air into the duct. An electronic monitoring system provides

read-outs of speed and distance, protects cable against duct obstructions, and

includes an emergency stop facility.

·

The air box and cable

pusher are mounted on a lightweight, tubular-steel frame that can be tilted at

a 30-degree angle to the manhole, which minimizes significantly any bending of

the innerduct and cable. The frame has height adjustment to permit ease of

maneuverability, and adjustable rear legs that provide added stability on

uneven terrain.

·

Can also be used

without the frame, directly from its skid

·

The Junction Box

Adapter is a necessary accessory for overriding existing cable in an occupied

duct (space permitting). One branch attaches to the Tornado for placing the new

cable or micro ducts, while the other branch seals off and holds the existing

cable in the duct (sold separately)

·

Included with the

Tornado is a convenient toolbox with all the tools needed for use and

maintenance of your blower

·

All relevant parts and

components of the cable blowing machine and the hydraulic power pack are

specially treated to resist corrosion

Operating Capacities

Pushing Force: 0-220 lbs.

(0-100kg)

Pushing Speed: 0-300 ft/min (0-90m/min)

Cable Size: .24-1.34″ (6-34mm) O.D.

Sub – Duct Size: 1/2-2 1/2″ SDR (12-63mm) O.D.

Pneumatic System

Air Hose Bore (min): 1 1/4″

(32mm)

Operating Pressure: 175 psi (12 bar)

Flow: The air

supply should be filtered, cooled and dry

For Ducts with an Inner

Diameter of: Minimum Flow

Acceptable @175 psi (12 bar)

0 up to 1″ (0 up to 25mm) : 150 CFM (4m³/min)

1 up to 1 1/8″ (26 up to 30mm) : 185 CFM (5m³/min)

1 1/8 up to 1 3/8″ (31 up to 35mm) : 250 CFM (7m³/min)

1 3/8 up to 1 5/8″ (36 up to 40mm) : 375 CFM (10m³/min)

1 5/8 up to 1 3/4″ (41 up to 44mm) : 450 CFM (12m³/min)

1 3/4 up to 2″ (44 up to 51mm): 700 CFM 19m³/min

IMPORTANT PRICING, CHECKOUT, AND SHIPPING INFORMATION!

***Due to continuous volatility of raw material costs seen industry wide, prices and availability are subject to change without notice. Confirmed updated pricing will be returned with shipping quotes within our two-step checkout process.***

We have a multi-step checkout process. Your initial online order does not have shipping costs included and will not be complete without a custom shipping quote. After you submit your initial online order, our Sales Team will generate a personalized quote with the most efficient shipping rate from the warehouse closest to you. You will receive a final quote that will include: updated pricing, estimated lead times, and shipping costs. If you have any questions about this process, please call us at 262-249-8705.