No products in the cart.

Pulling vs. Blowing Fiber: A Beginner’s Guide – Part 2

Home Pulling vs. Blowing Fiber: A Beginner’s Guide – Part 2

- Home

- Resource Hub

- Millennium Blog

- Pulling vs. Blowing Fiber: A Beginner’s Guide – Part 2

Pulling vs. Blowing Fiber: A Beginner's Guide - Part 2

Blowing Fiber Basics

Blowing fiber, or jetting, is when a machine floats or pushes fiber optic cable forward through the conduit run with highly pressurized air. While the set-up is more involved, blowing fiber is great for long distances and can go thousands of feet.

Benefits of blowing fiber:

- Fewer splice points and handholes needed

- Fewer crew members needed for fiber deployment

- Save of material and labor costs

- Efficiencies of scale across longer distances

Employee wages are oftentimes the largest cost associated with fiber network builds, and fiber blowing machines can lower these labor costs by reducing installation time. However, blowing fiber is a relatively new technology; training is required to operate, install, and maintain the equipment properly.

How to blow fiber

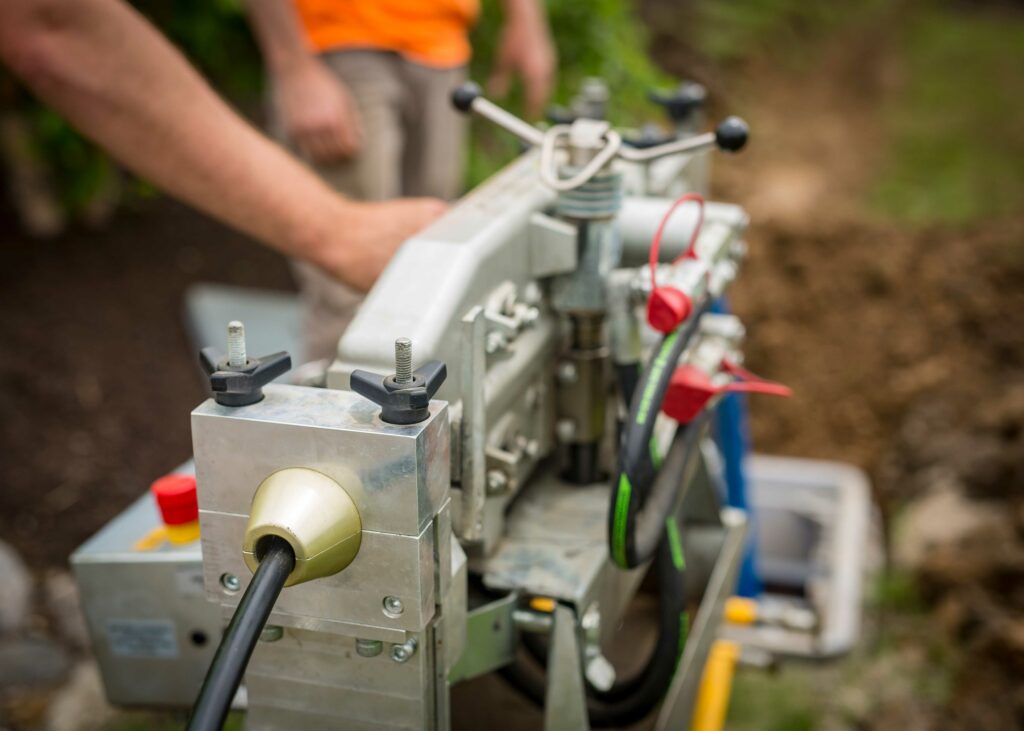

Blowing fiber begins with setting up and configuring your blowing machine. The blower needs to be configured correctly for your fiber and duct sizes; these parts will change depending on your fiber diameter and conduit size. Make sure to have the right collets, clamps, plugs, and seals on hand before you begin set-up. Your blowing machine setup must include a hydraulic power pack and air compressor.

1. Proof your duct

Once the equipment is ready, proof your duct by blowing a duct projectile or sponge through the conduit run to remove any debris or obstacles.

Image credit: GMP

2. Perform a crash test

Before you begin blowing fiber, you may also want to perform a crash test to establish the integrity of the duct. This is especially important if you are new to blowing fiber or have a new machine.

How to Perform a Crash Test – Put a small amount of fiber into the duct to simulate a fiber run and what would happen if the fiber runs into an obstacle while you are blowing. This test helps show how the fiber-blowing machine reacts and what to look for in the gauges if an object is hit. Pay attention to whether the air pressure increases or the fiber slows down. We recommend doing a crash test at least a few times while learning how to install blown fiber. An experienced crew may not need to do this step if they already know what to look for on their machine when fiber hits an obstruction within the conduit.

3. Begin Fiber Prep

To prepare your fiber, a cable grip, and an appropriately sized carrier or parachute should be attached to the end of the fiber. This allows the compressed air to push the parachute through the conduit while the carrier pulls the attached fiber. Blowing lube should be applied to the opening of the duct before you start blowing the fiber and applied to the fiber as it enters the duct.

4. Start Blowing Fiber

After the fiber is properly prepared, it should be pushed into the duct a few hundred feet using the tracks on the machine without having the air compressor on. At least one person is needed to watch the machine and the gauges for proper operation and then a second person to watch the fiber to ensure it is coming off the reel properly and then receive it once it is near the end of the run. After verifying the machine is running smoothly, and the fiber is inside the duct a couple hundred feet, the air compressor should be turned on for the remainder of the installation. An experienced crew can blow nearly 2-3 miles of fiber in a few hours.

It may take longer for the initial set-up, but blowing fiber for longer runs makes installation faster. A cable can easily go a few thousand feet in one run, so there are fewer touchpoints along the run, making fiber blowing extremely efficient. Blowing also puts less strain on the fiber, resulting in a smaller chance of damage, and is the preferred method if the duct run has multiple bends.

Daisy Chaining: A Fiber Blowing Method for the Experts

If a fiber installer is highly experienced and knowledgeable about the nuances of calibrating fiber blowers, daisy chaining is another method of fiber blowing that can drastically increase efficiency. Daisy chaining is an advanced process connecting multiple fiber blowers, usually 2 to 3 in a row, to blow fiber faster across an extended run. This process should be reserved for experienced fiber blowers who understand proper machine setup, calibration, and synchronization for this procedure. Improper machine setup can cause too much air pressure across the chain, which could damage either the fiber blower, the fiber-optic cables, or both. Even expert fiber installers are advised to consult with the equipment manufacturer on how to use this advanced method.

Read “5 Tips for Blowing Fiber Further” for more ways to give your team an edge while blowing fiber.

Easier Network Future Proofing

Fiber blowing offers a lot of flexibility that aids network scalability. One method to scale a network is to overblow cable by blowing in more fiber into the existing occupied duct. Because the cable floats in the air, there is a reduced chance of friction as more cable is installed beside the existing fiber. Another method is through the use of MicroTechnologies. A bundling of microducts, like DuraLine’s FuturePath, allows for multiple pathways to be installed in the future without disrupting service for current subscribers. Interested in learning about other ways to scale your network efficiently? Read our blog “5 Tips for Future-Proofing Your Network” to get started.

What fiber blower equipment to use

When choosing a fiber blower to use, General Machine Products or GMP is a brand worth considering. GMP is a popular broadband equipment manufacturer whose aerial cable lashing machines, fiber-optic cable pullers, and fiber blowing machines are considered industry standards.

Watch the video to learn about popular GMP fiber blowers and their applications.

Our fiber blowing equipment recommendations:

- For traditional fiber: Tornado Plus Fiber Blower.

- For MicroFiber: Hurricane Plus Fiber Blower.

- See what fiber blowing accessories are available.

This is Part 2 of our 3-part series: “Pulling vs. Blowing Fiber: A Beginner’s Guide.” For more information and tips, check out Part 1 | Part 3

If you have any questions, contact a Millennium Rentals & Leasing Expert.

- Feasibility Studies & Network Design Plans

- Financing & Grants

- Project Resource Management

- Material Supply & Logistical Planning

- Equipment Leasing & Rentals